Semi-Automatic Loading and Packaging of Salami Slicing-Logs in France

Starting situation:

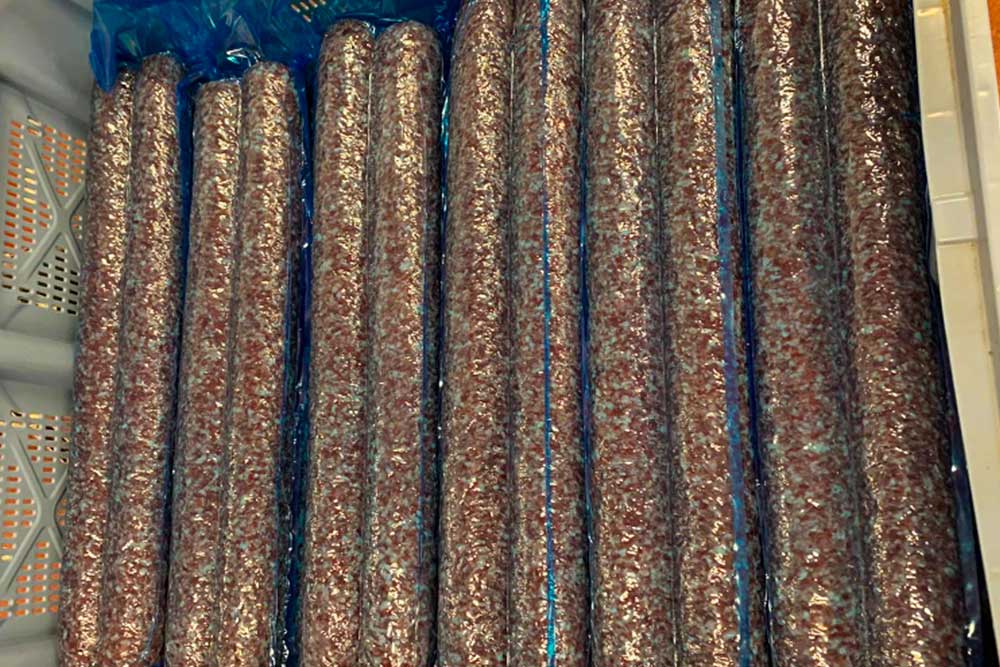

For more than three generations, raw sausage has been produced by the customer at three sites in France. Today, the company belongs to a major supermarket chain. A wide variety of raw sausage is produced for various brands. In this project, slicing-log goods with a diameter of 30-90 mm and in lengths up to 950 mm are packaged. Depending on the product, between 1 and 6 products per bag are vacuum-packaged.

Challenges:

The process today is pretty much done manually. The products must be peeled manually or semi-automatically. Subsequently, they are packaged on double chamber machines. The difficulty was to boost the automation of the process in general because many steps were quite labor-intensive and cumbersome. Another challenge for Supervac was to establish communication with other machines in the semi-automatic production line of the project partner.

Our solution:

First, we integrated our project partner’s automatic peeling machine, bagging solution and conveyors. Signals are exchanged, and an emergency-stop chain is ensured. The packaging of the raw sausage slicing-logs is done on a Supervac GK 612 B with a split belt. Then the vacuum-packaged products are transported from the chamber and are buffered on an outfeed roller table. The customer is thoroughly delighted with the solution because the time spent at manual work has been considerably cut down, and the process runs continuously and safely.